Ptfe Laminated Glass Fabric

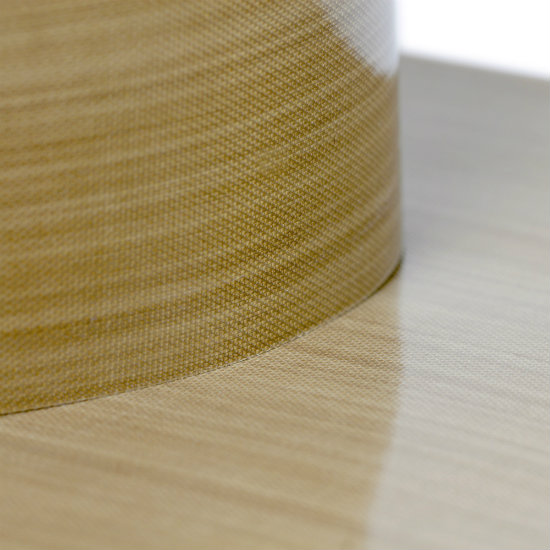

Conventional ptfe coated fabrics are built up of multiple coating layers of ptfe.

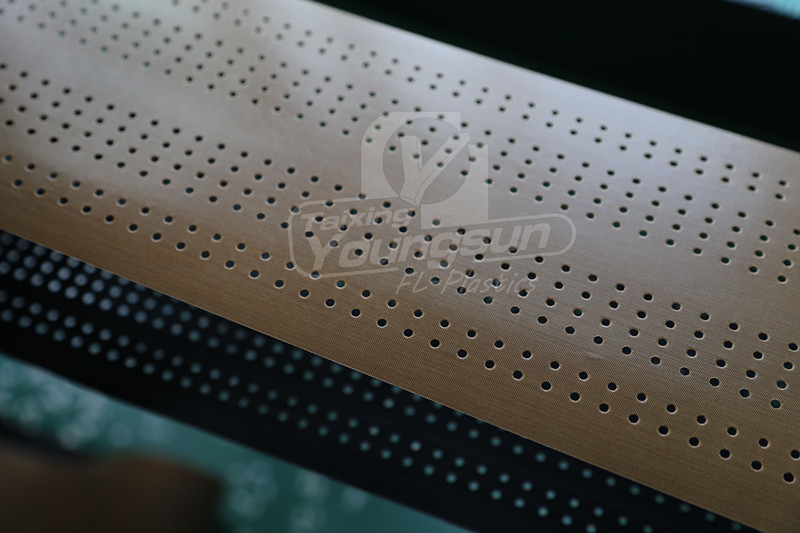

Ptfe laminated glass fabric. Ptfe film laminate glass cloth. Ptfe coated fiberglass fabric cloth. Porous grade ptfe fabric. Their unique properties provide the longest lasting and most consistent performance for applications where non stick release.

Fiberflon recommends fiberlam series film laminated materials for wet applications which features a multilayer cast film is laminated to the gas side and provides an extra layer of protection against corrosive chemicals. Friction control insulation dielectric control or barrier protection is a challenge. It uses open mesh glass fabric with a coating of ptfe that ranges from breathing to 0 25 inch mesh. This is done by running the substrate through a dip bath of ptfe dispersion then drying and sintering the ptfe to form a smooth layer.

Ptfe prepreg fabric is used in ccl production in order for meeting the high frequency request in 5g. Chemfab products are coated or laminated composites comprising of glass or aramid fabrics and silicone or ptfe. Under practical situation of high temperature of 250 c for 200 days not only the intensity will not decrease the weight will not reduce. Ptfe glass coated fabric for copper clad laminate ccl ptfe glass coated fabric is using e glass fiber or kevlar nomex as basic fabric and impregnated with high quality ptfe teflon polytetrafluoroethylene.

1 ptfe coated fiberglass fabric cloth can be used under the temperature of 70 c 260 c which has the capacity of weather resistant and age resistant.