Flexidry Floor Screed

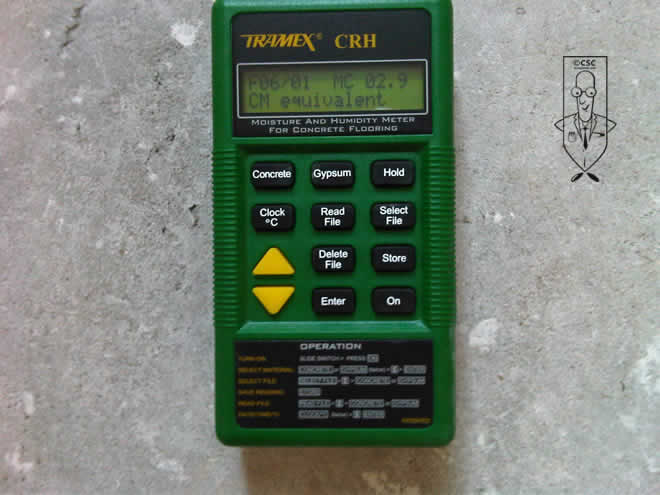

Testing of the screed moisture testing.

Flexidry floor screed. The recognised testing method for flexidry floor screeds is a carbide bomb test which should always be carried out before laying sensitive floor coverings. Flexidry a floor screed additive that dramatically reduces drying times. Products with have technical specifications. The various flexidry fast drying floor screeds include flexidry f0 with a drying time of just 3 days flexidry f1 which dries in 7 days flexidry f2 which takes 14 days and flexidry f3 which takes 21 days to dry.

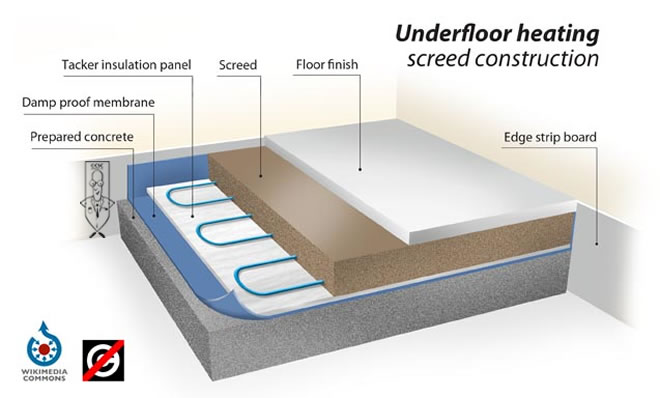

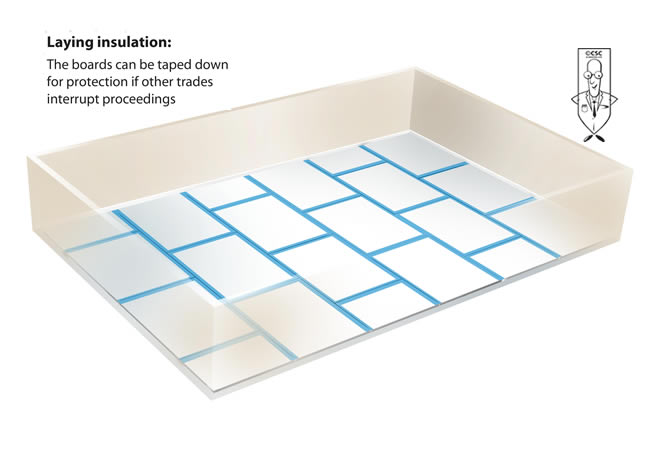

All these screeds make it possible to let light foot traffic proceed within 12 hours of installation. By altering the dosage the dry time of the screed can be chosen at 7 14 or 21. An advanced and highly adaptive fast drying screed additive flexidry is an advanced and highly adaptive screed system which can be used on a wide range of floor applications. Standard floor screed dries at a rate of 1mm per day up to 40mm and 0 5mm per day thereafter.

Flexidry is an accelerated screed additive which can be used on a wide range of floor applications. For the promised features and the effect of the flexidry f0 formula. The recognised testing method for flexidry floor screeds is a. Having already been used successfully in thousands of projects across europe flexidry is a cost effective accelerated screed system which can be used on a wide range of floor applications giving a choice of dry times of 7 14 or 21 days.

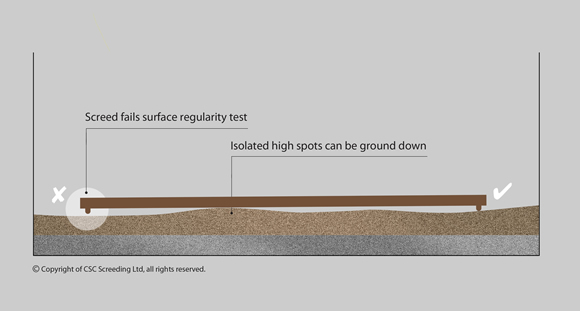

Flexidry global ltd hasn t formatted technical specifications for flexidry floor screeds yet. Floor screeding the essential guide to floor screeding last updated 03 feb 2013 csc screeding. This would normally mean that a 75mm standard screed application would take 110 days at 20c to receive a sensitive final floor finishings and this is something that is quite often overlooked. Please check out the similar products section for alternatives.

Why wait 110 days for your floor screed to dry when you can choose 3 7 14 or 21 days.